Secure manufacturing of IoT products at scale is an often overlooked challenge.

The Electric Imp platform implements a fully connected manufacturing process enabling you to securely and efficiently build IoT products at scale.

Secure manufacturing of IoT products at scale is an often overlooked challenge.

The Electric Imp platform implements a fully connected manufacturing process enabling you to securely and efficiently build IoT products at scale.

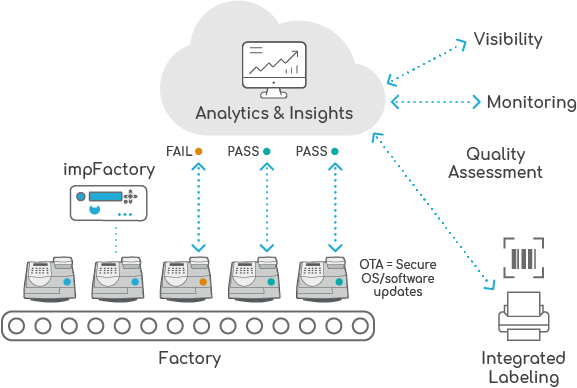

As your products come down the assembly line, the factory process is controlled by the impFactoryTM device. Each imp Module embedded in your product connects to the Electric Imp Managed Cloud, receives software and configuration data, and reports its status as it moves down the line. When all steps have been successfully passed, the latest production software is loaded and the product is ready to be boxed and shipped.

Connected manufacturing gives you valuable real-time visibility and control of the factory process, including fully automated customization and serialization of products and insights into production quality and quantity.

Critically, the Electric Imp connected manufacturing process enforces strict security boundaries in the factory and along the entire supply chain, featuring locked-down modules, secure OTA (over-the-air) updates, and encryption of all customer and product data — ensuring your intellectual property is secure and your products can be trusted, even in unprotected environments.