Effectively monitoring and controlling your products and services allows you to detect and avoid failures, improve operational efficiency, and enables value-added processes and services. These are increasingly critical requirements for companies in many industries, driving the need for real-time insight into the status and operation of commercial equipment and industrial machines.

The new revenue and efficiency advantages enabled through IoT monitoring and control of commercial and industrial equipment will transform your business in ways only imagined a few years ago.

- Reduce cost due to service interruptions, equipment failures, and theft

- Improve ROI of equipment and processes by optimizing operation

- Enable new business models such as ‘equipment-as-a-service’

Developing and maintaining an IoT connectivity solution for monitoring and control applications is complex. It requires considerable experience in several areas that most organizations lack. These include device-to-cloud security, hardware design, communications technologies, cloud infrastructure, and ongoing security and platform maintenance.

More specific challenges are:

- Supporting devices in a wide variety of indoor, outdoor, and remote locations

- Reliably detecting time-critical out-of-bounds conditions, failures, and theft

- Integration with existing systems

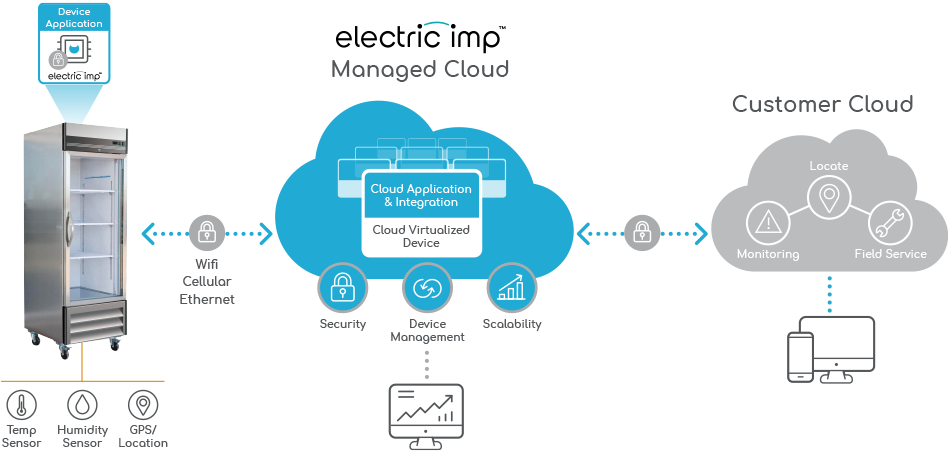

The Electric Imp IoT Connectivity Platform supports a wide range of monitoring and control use cases as it can flexibly and seamlessly adapt to customer equipment and applications with a single architecture.

The Electric Imp offering addresses the three main customer needs:

- Implements end-to-end security from the equipment to the cloud (UL 2900-2-2 cybersecurity), including continuous security maintenance

- Implements fast and reliable operations and communication to ensure critical events are delivered

- Supports existing equipment, machines, back-end systems, and use case-specific business logic

The Electric Imp platform uniquely combines everything you need to quickly add remote monitoring and control capabilities to your equipment. Device-to-cloud security, connectivity, energy management of battery-powered devices, integrating with back office systems — all are built into the Electric Imp platform so you can focus on your core competencies and go from prototype to production quickly.

Commercial Refrigeration Monitoring

The potential of remote monitoring and control is recognized by all companies involved in “cold chain services,” which ensure that billions of dollars worth of perishable goods are kept cold from point of origin to final destination — including any planes, trains, trucks, and warehouses in between.

With IoT, companies can now monitor temperature, location, and other operating characteristics in real-time as well as physically track mobile refrigeration units to prevent theft.

The Electric Imp IoT Connectivity platform enables real-time monitoring and control of refrigeration units in the field. It supports a variety of connectivity options, including cellular, and provides seamless integration into back-end systems.